Process

- Aside supplying OEM/ODM customizing parts, we are also providing sub-component assembly service.

- With implementation of SOP, functional testing and dimensions verification, we are confident that our products will meet the highest quality standard.

Plastic Parts

Material: PE, PP, PC, ABS, PVC, PS, etc.

Processing method: Injection, blow molded, extruded, thermal form, milling ,grinding,turning,etc.

Surface treatment: painting, screen printing, electroplating, etc.

Product inspection: initial sample inspection, process quality control, Pre-shipment Inspection.

Inspection tool: Coordinate Measuring Machine, Projector, all kinds of gauge.

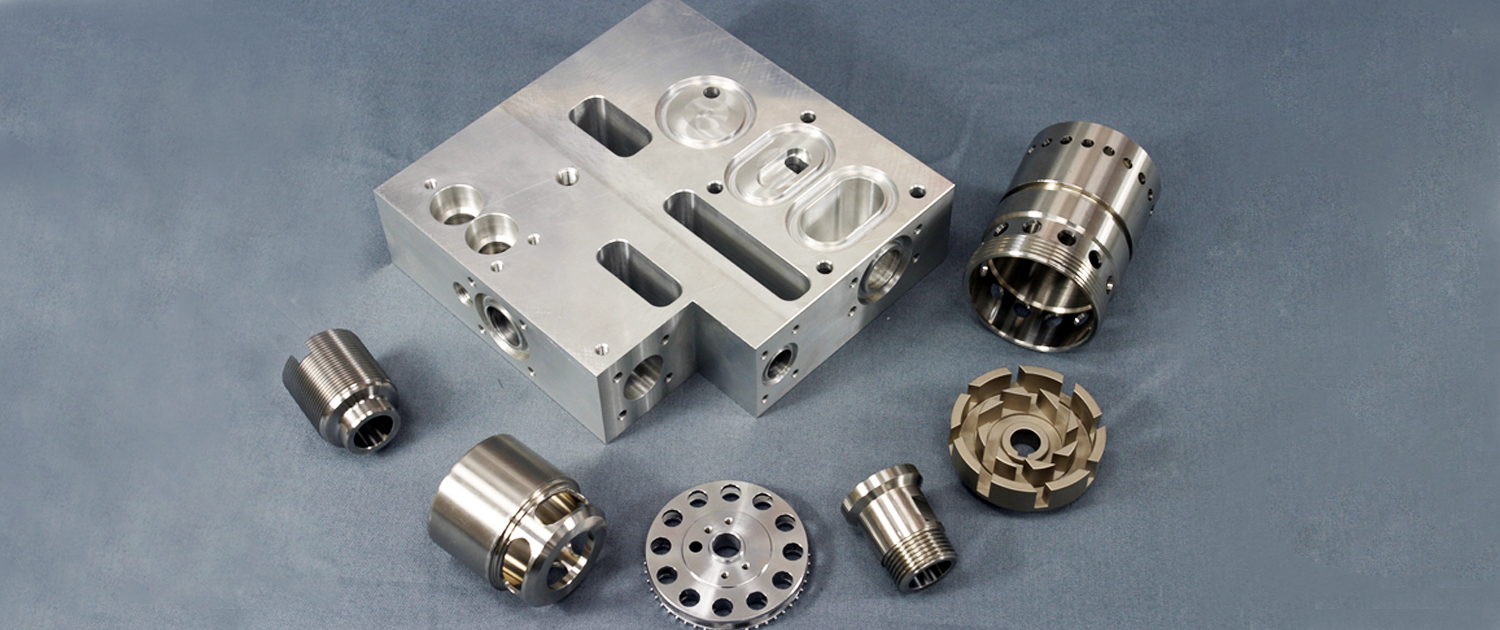

Material: Precision machining-All metal material

Processing method: milling , grinding, turning ,drilling, reaming, tapping, boring, slotting, etc.

Surface treatment: painting, electroplating, oxygenation, etc.

Product inspection: initial sample inspection, process quality control, Pre-shipment Inspection.

Inspection tool: Coordinate Measuring Machine, Projector, all kinds of gauge.

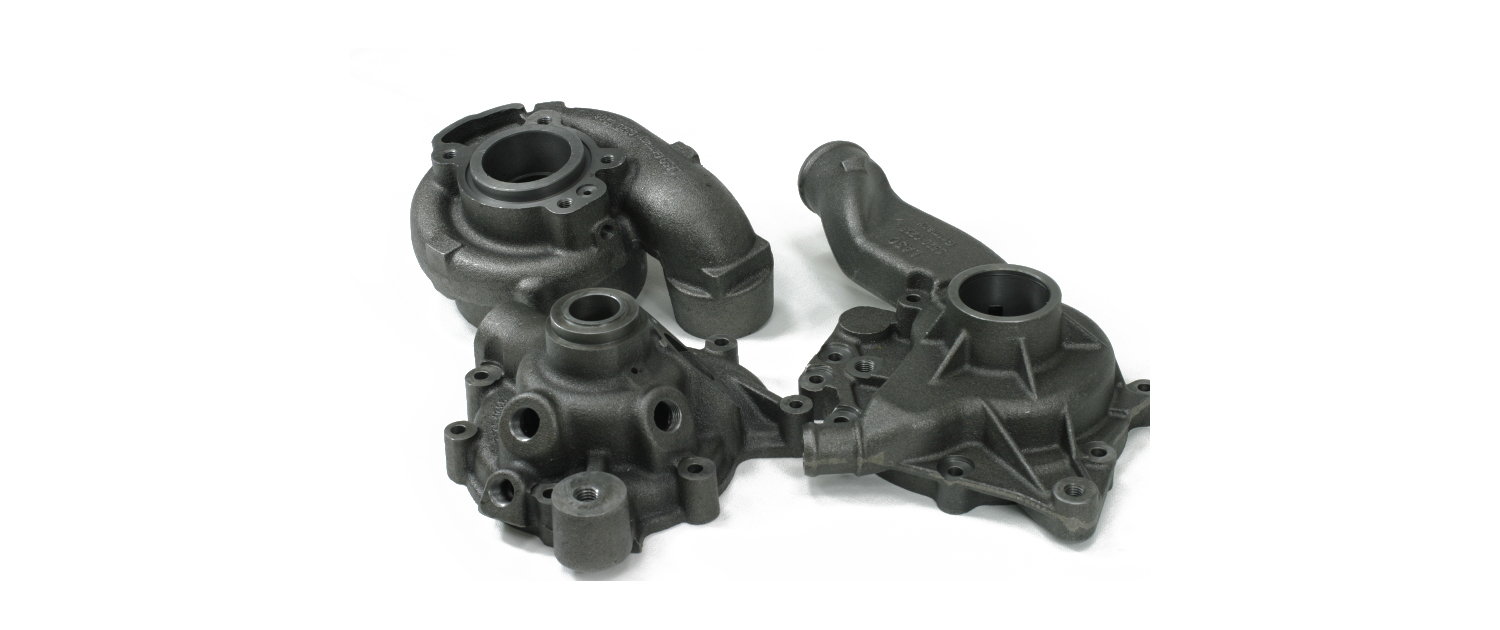

Precision Investment Casting

Material: Precision Investment Casting-carbon steel,Precision Investment Casting-Alloy steel,Precision Investment Casting-stainless steel ,etc.

Processing method: turning, milling , drilling, boring, slotting, rolling, tapping.

Surface treatment: painting, electroplating, Shot blasting, etc.

Product inspection: initial sample inspection, process quality control, Pre-shipment Inspection.

Inspection tool: Coordinate Measuring Machine, Projector, all kinds of gauge, Salt Spray Tester, etc.

Forging

Material: Forging-aluminium,Forging- brass,Forging- carbon steel,Forging-stainless steel,etc.

Processing method: turning, milling , drilling, boring, slotting, rolling, tapping, reaming.

Surface treatment: sand blasting, zinc coating, hot-dip galvanizing , powder coating, chrome coating. , oxygenation, etc.

Product inspection: initial sample inspection, process quality control, Pre-shipment Inspection.

Inspection tool: Coordinate Measuring Machine, Projector, all kinds of gauge.

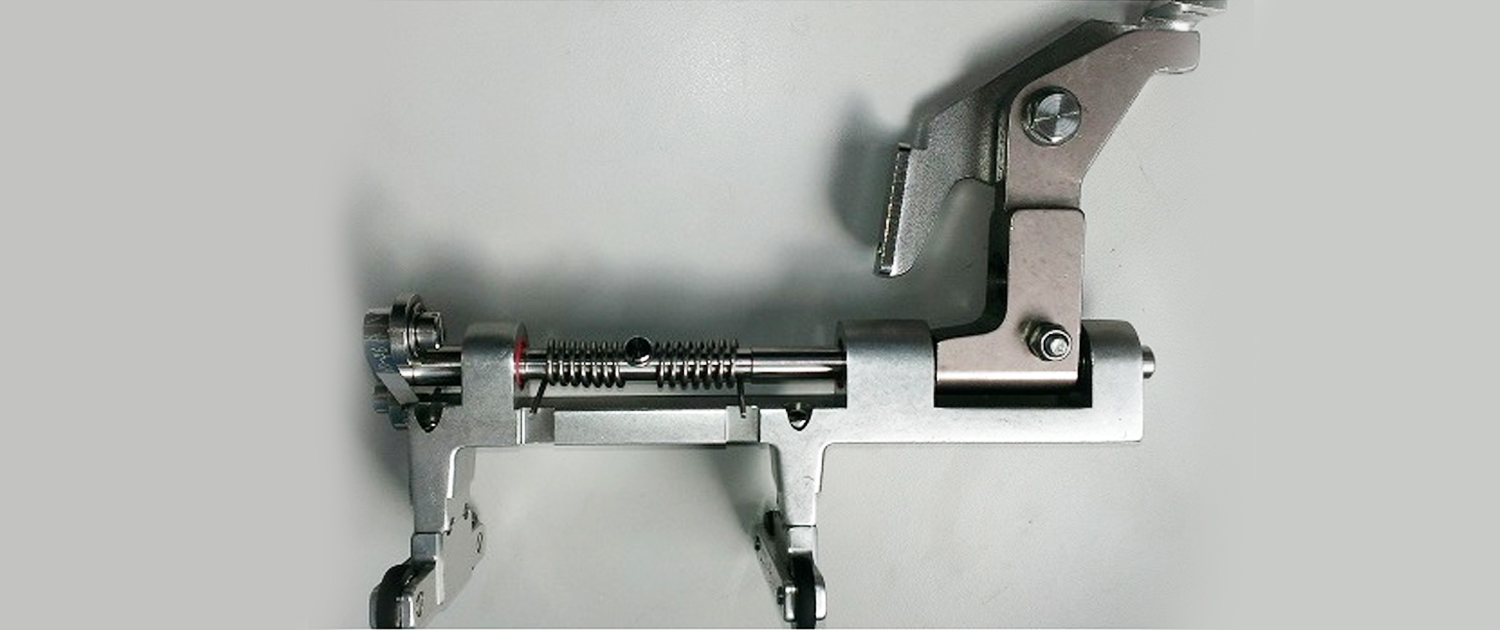

Assembly

- Aside supplying OEM/ODM customizing parts, we are also providing sub-component assembly service.

- With implementation of SOP, functional testing and dimensions verification, we are confident that our products will meet the highest quality standard.

Die Casting

Material:Gravity Die Casting-A356,Gravity Die Casting-ZL101, etc

Processing method: turning, milling ,grinding, drilling, boring, slotting, rolling, hobbing, tapping,etc

Surface treatment:painting, powder coating, electroplating, oxygenation,Shot blasting, etc.

Product inspection: initial sample inspection, process quality control, Pre-shipment Inspection.

Inspection tool: Coordinate Measuring Machine, Projector, all kinds of gauge,Salt Spray Tester, etc.

We can make the customized parts according to customer’s requirement. g-A356,Gravity Die Casting-ZL101, etc

Stamping

Material: different steel,aluminium,brass ect

Processing method: Bending, flanging, embossing, blanking, coining, drawing, stretching, curling, hemming, etc

Surface treatment:Anodizing, Powder-Coating, Zinc-Plated, Chrome coated ,Nickel Plated ,Hex Chromates Zinc, Rust-inhibiting oils, Electrophoresis, Paints and primers, blacking, etc

Product inspection: initial sample inspection, process quality control, Pre-shipment Inspection.

Inspection tool: Coordinate Measuring Machine, Projector, all kinds of gauge,Salt Spray Tester, etc.